TLDR:

- Purging compounds clean blown film extruders and die heads

- Reduce downtime during resin and color changeovers

- Improve film quality and minimize material waste

- Support consistent mechanical properties in multi-layered films

- Help optimize productivity in the packaging industry and beyond

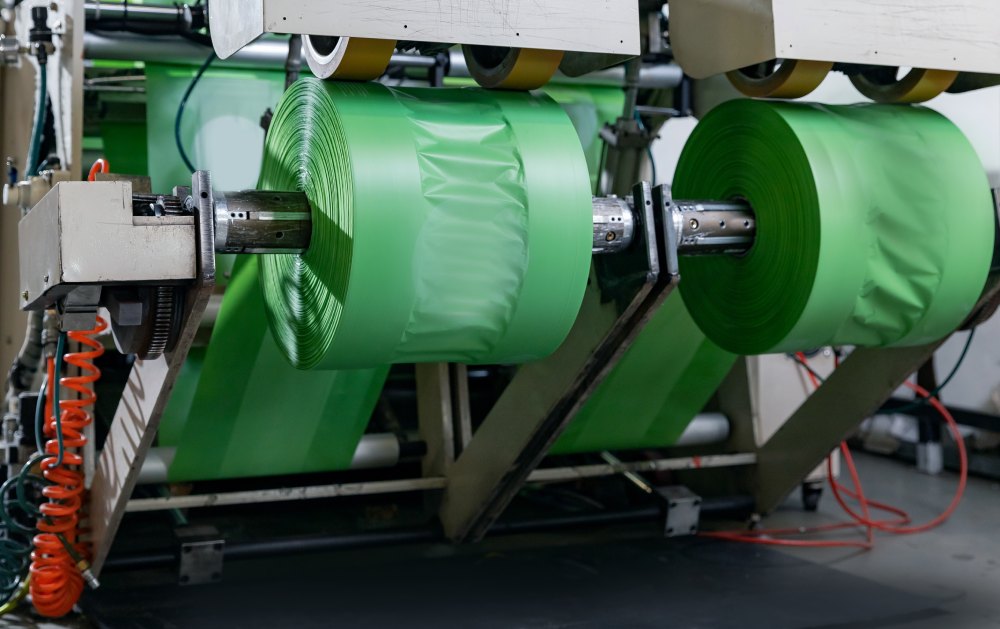

In the fast-paced plastics industry, blown film manufacturers must strike a balance between speed, quality, and cost-efficiency. However, contamination, color streaks, and long changeover times can disrupt the manufacturing process, leading to excessive waste and costly downtime. That’s where a purging compound for blown film production becomes a game-changer.

Whether you’re producing food packaging, multi-layered films, or industrial film products, regular purging is essential to maintaining high efficiency and consistent product quality.

Challenges in the Blown Film Extrusion Process

The blown film extrusion process involves melting plastic resins—such as polyethylene (LDPE, HDPE, and LLDPE)—and forming a bubble through a circular die. As simple as it sounds, this process is highly sensitive to material contamination, especially during resin or color transitions.

Common issues include:

- Residual material left in the blown film extruder

- Buildup in the die head

- Streaks and specks in the film

- Inconsistent mechanical properties in high quality plastic films

These problems directly impact the properties of the film, particularly in the packaging industry, where clarity, thickness, and strength must meet strict standards.

How Purging Compounds Improve Efficiency

Using a purging compound in blown film production helps minimize these issues by thoroughly cleaning the screw, barrel, and circular die. Here’s how it supports a more efficient operation:

- Reduces downtime during resin and color changes

- Cuts material waste by preventing off-spec startup scrap

- Cleans the die head without disassembly

- Maintains consistent film quality and gauge control

- Extends the life of equipment and tooling

By integrating a regular purging process, manufacturers gain tighter control over their blown film extrusion lines, ultimately boosting productivity and reducing overall operating costs.

Compatible with a Wide Range of Applications

Modern purging compounds are engineered for compatibility with a wide range of plastic resins, including the common blends used in flat film and blown extrusion film applications. These compounds are also safe for use in hot runner systems, where gentle yet thorough cleaning is essential to prevent wear.

Whether you’re producing:

- Clear food packaging

- Multi-layer barrier films

- Durable industrial sheeting

…a high-performance purging compound can enhance every phase of the manufacturing process.

Easy Integration with Long-Term Benefits

The good news is that implementing a purging process doesn’t require major changes. Many suppliers offer a free sample, making it easy to test and validate the results on your own blown film extruder.

Once integrated, purging becomes a simple step that pays off in:

- Cleaner startups

- Fewer production errors

- More consistent film quality

- Lower long-term maintenance costs

The Bottom Line

For blown film producers aiming to improve efficiency, a purging compound for blown film production is more than a maintenance tool—it’s a strategic advantage. By reducing waste, shortening changeovers, and improving film properties, it allows you to meet growing demands in the packaging industry with greater consistency and confidence.

Try a free sample and see how the right purging solution can transform your blown film extrusion line.