TLDR

- Purging compounds keep injection molding machines and hot runner systems clean

- Prevent black specks, color contamination, and high scrap rates

- Use proper soak time for effective cleaning

- Apply at color/material changes and shutdowns

- Access purging compound tips, FAQs, and resources to optimize plastics processing

When it comes to plastics manufacturing, downtime, contamination, and wasted resin can cost thousands. That’s why many processors turn to purging compounds. But what exactly should you know before using them?

Here are six common purging compound questions—and the answers every manufacturer needs.

1. What is a purging compound, and why is it important?

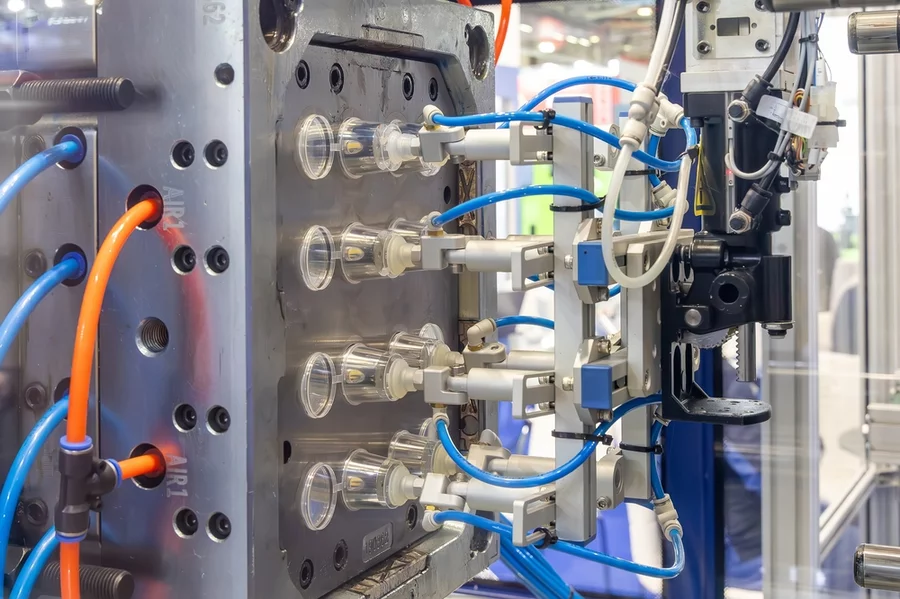

A purging compound is a specially formulated resin blend used to clean injection molding machines, molding machines, and hot runner systems. Unlike production resins, which simply push out old material, purging compounds are engineered to remove stubborn contamination, degraded polymer, and color residue. Using them reduces scrap rate, improves product quality, and minimizes costly downtime.

2. Can’t I just use production resin or regrind instead?

This is one of the most common purging compound FAQs. While some manufacturers try to purge with regrind or virgin resin, these materials often fail to remove stuck-on residue. Over time, this causes black specks, color streaks, and even carbon buildup inside barrels and screws. A good purging compound is designed for effective cleaning and saves money in the long run.

3. How does the purging process actually work?

The purging process depends on the machine and material being used, but most involve three steps:

- Emptying production resin from the barrel and screw

- Introducing the purge and cycling it through the machine

- Following the recommended soak time to let the compound break down contamination

By combining mechanical action with foaming properties, Purgex grades act as a purge that expands into tight spaces, ensuring no residue remains.

4. Which machines and processes benefit most from purging compounds?

Purging compounds aren’t limited to one type of machine. They’re used in:

- Injection molding machines: to clear out color and resin between jobs

- Hot runner systems: to prevent trapped molten material from degrading

- Extruders and blow molding equipment: to reduce changeover times and improve consistency

Wherever plastics processing takes place, a purge can protect equipment and improve efficiency.

5. How often should I purge my machines?

There’s no single answer—it depends on your molding process and materials. Best practice is to purge at every color changeover, during material transitions, and before scheduled shutdowns. Many manufacturers also integrate purging into a preventive maintenance plan to stop contamination before it starts.

6. What resources are available to help me choose the right purge?

Not all compounds are created equal, and choosing the wrong grade can waste money. Fortunately, there are many purging compound resources available. Purgex provides technical support, training, and customized purging compound tips for specific resins, temperatures, and equipment. We offer product trials, purging compounds information guides, and direct consultation to ensure you get the right solution.

For More Information:Read Our Purging Compound Case Studies

The Bottom Line

Whether you’re dealing with color contamination, black specks, or long downtime, purging compounds are a proven way to protect your process. By asking the right questions and working with an experienced supplier, you can reduce scrap, improve quality, and keep your equipment running at peak performance.