Clean Transitions. Less Downtime. Better Results.

Injection Molding Procedure – Barrel, Screw, Check Ring and Nozzle.PDF

Injection Molding Procedure – Hot Runner System Open Mold.PDF

When it comes to purging injection molding machines, contamination isn’t just an inconvenience—it’s a cost. Scrap parts with color streaks or black specks, add up and are a sign of an inefficient process. Purgex offers high-quality purging compounds designed for injection molding applications so you can reliably attain consistent, defect-free production.

Purging Compounds Built for Injection Molding Performance

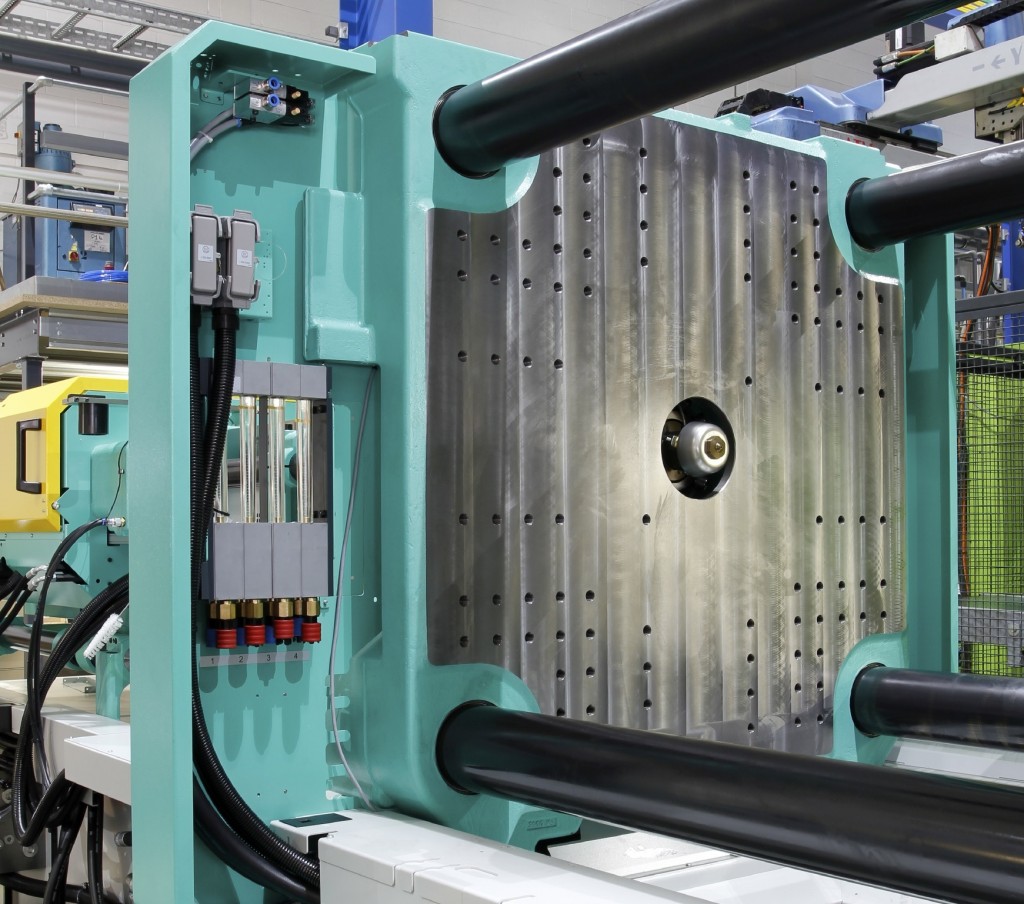

From large automotive IPs and consoles to small caps and closures, precision matters. The purging process for in injection molding needs to clean every inch of the system, including tight spaces inside the injection unit, barrel, screw, check ring, mixing nozzles, and hot runner systems, including the tips.

Purgex offers:

- Hybrid (mechanical and chemical) purging compounds for thorough and efficient cleaning, plus foaming action for enhanced mixing, and a lubricant for easy removal.

- Grades for difficult applications.

- General purpose grades that effectively clean a wide variety of resins.

- All Purgex grades are safe and recommended for hot runner systems.

Our purging solutions are designed to rinse clean, leaving no residue behind, preventing contamination during your next run.

Injection Molding Purging Methods: Why It Matters

The most efficient molding operations rely on consistent purging to maximize uptime and minimize waste. Purgex compounds streamline your purging processes with foaming action that thoroughly cleans, reducing the need for long extended machine downtime.

Key benefits of using Purgex in your injection molding machines and extruders:

- Reduces machine downtime and boosts productivity

- Eliminates color and material residue between runs

- Reduces scrap and costly product defects

- Compatible with high-performance and filled resins

Purging Compound for Hot Runner Systems & Closed Molds

Not all compounds are safe for hot runner systems, but Purgex is different. Our purging compounds are engineered for smooth flow through and manifold systems, even in high-cavitation tools.

We offer:

- Purging compounds for hot runner systems that won’t clog or degrade components

- Purging compounds for use in open and closed molding procedures

- Compatibility with complex systems including side gates, valve gates, and multi-material molds

Whether you’re running legacy or modern tools, we have a solution tailored to your situation.

Covering More Than Injection Molding

While Purgex is optimized for purging injection molding machines, we also support:

- Extrusion lines

- Blow molding systems

- Film (cast and blown), and sheet production lines

No matter the thermoplastic molding application, we provide highly effective purging solutions that keep injection molding machines running at peak performance.

How Purgex Improves Material Changeovers

Color or material changeovers are a regular part of production—but they don’t have to lead to delays and scrap. With Purgex, you can expect:

- Faster transitions between runs

- Fewer rejects due to contamination

- Consistent product quality from the first shot

- Less reliance on machine teardown and manual cleaning

By choosing the right purging compound for injection molding, you get more control over your schedule, resin usage, and part quality.

Request a Sample or Get Support

Want to try Purgex on your injection molding machines? We make it easy to evaluate our purging compounds by offering fast sample shipments and expert support.

Let us help you find the right product for:

- Your location (so your local technical sales rep can follow up)

- Your molding process (injection molding, extrusion, blow molding, etc.)

- Your material type (commodity resins, engineering plastics, filled resins)

Explore Our Injection Molding Purging Videos

Watch Purgex in action! See how our product handles a red-to-green color change on a real injection molding machine.

For more case studies and purging process tips, visit our video library.

Discover the Best Purging Solution for Your Operation

Purgex was built with injection molders in mind. Whether you’re fighting material hang-up, prepping for a color change, or working with complex molds and hot runner systems, Purgex products help you clean your machines faster and completely.

Choose a commercial purging compound trusted by manufacturers for over 30 years. Browse our product selector, request a sample, or talk to your local technical rep today.